Lightning is a powerful and unpredictable natural phenomenon that can cause significant damage to buildings, infrastructure, and human life. Lightning strikes can result in fires, structural damage, and damage to electrical systems and equipment. As a result, it is essential to implement lightning protection systems for buildings to minimize the risk of damage and ensure the safety of building occupants. In this article, we will discuss lightning arresters for buildings.

One of the most critical components of a lightning protection system for buildings is a lightning arrester. Lightning arresters are devices that are designed to protect electrical systems and equipment from high-voltage surges caused by lightning strikes. Two of the most common types of lightning arresters used for buildings are the Franklin rod air terminal and the ESE lightning arrester.

Franklin Rod Air Terminal

The Franklin rod air terminal, also known as the Franklin lightning rod, is a simple and effective method of lightning protection. The Franklin rod air terminal was first introduced in the mid-18th century by Benjamin Franklin, who discovered that lightning was a form of electrical discharge. The Franklin rod air terminal consists of a metal rod or rods that are installed on the roof of a building and connected to a grounding system.

The Franklin rod air terminal works by creating a path of least resistance for the electrical current produced by a lightning strike. When lightning strikes the Franklin rod air terminal, the electrical current is directed to the grounding system, preventing it from traveling through the building’s electrical systems and equipment.

The Franklin rod air terminal is a reliable and cost-effective method of lightning protection, making it a popular choice for many buildings. However, it has some limitations. The Franklin rod air terminal is not effective against direct lightning strikes that occur within a few hundred feet of the building. Additionally, the Franklin rod air terminal must be installed correctly to be effective. If it is not installed correctly, it can actually increase the risk of damage from lightning strikes.

ESE Lightning Arrester

The ESE lightning arrester, also known as the early streamer emission lightning arrester, is a more advanced type of lightning arrester that provides a higher level of protection against lightning strikes. The ESE lightning arrester was first introduced in the 1970s and has since become a popular choice for modern buildings.

The ESE lightning arrester works by emitting a streamer that travels toward the approaching lightning strike. The streamer ionizes the air, creating a path of least resistance for the electrical current produced by the lightning strike. This allows the electrical current to be safely diverted away from the building’s electrical systems and equipment.

The ESE lightning arrester provides a higher level of protection against lightning strikes than the Franklin rod air terminal. It is effective against direct lightning strikes that occur within a few hundred feet of the building, as well as indirect lightning strikes. Additionally, the ESE lightning arrester can be installed at a lower height than the Franklin rod air terminal, reducing the visual impact on the building’s design.

Choosing the Right Lightning Arrester for Your Building

When it comes to choosing the right lightning arrester for your building, there are several factors to consider. These include the type of building, the height of the building, and the local weather patterns.

For buildings that are less than 75 feet tall, the Franklin rod air terminal is a reliable and cost-effective method of lightning protection. However, for taller buildings or buildings located in areas with a high risk of lightning strikes, the ESE lightning arrester is a better choice. The ESE lightning arrester provides a higher level of protection against lightning strikes and can be installed at a lower height, reducing the visual impact on the building’s design.

It is also important to consider the local weather patterns when choosing a lightning arrester for your building. Buildings located in areas with a high frequency of thunderstorms and lightning strikes will require a more robust lightning protection system than buildings located in areas with a lower frequency of thunderstorms and lightning strikes.

In addition to choosing the right type of lightning arrester, it is important to ensure that the lightning protection system is installed correctly. Lightning protection systems must be designed and installed by professionals who are trained in lightning protection systems. They must also comply with national and international standards for lightning protection, such as NFPA 780 and IEC 62305.

Surge Protection Systems

In addition to lightning arresters, surge protection systems are an important component of a comprehensive lightning protection system for buildings. Surge protection systems are designed to protect electrical systems and equipment from power surges caused by lightning strikes, as well as other sources of electrical surges, such as power outages and equipment malfunctions.

Surge protection systems work by limiting the voltage of an electrical surge, preventing it from damaging electrical systems and equipment. Surge protection systems can be installed at the building’s service entrance, as well as at individual electrical panels and equipment.

There are several types of surge protection systems available, including transient voltage surge suppressors (TVSS), surge protective devices (SPD), and power conditioners. TVSS and SPD are the most common types of surge protection systems used for buildings.

Transient Voltage Surge Suppressors (TVSS)

TVSS are a type of surge protection device that is designed to protect electrical systems and equipment from transient voltage surges. TVSS are typically installed at the building’s service entrance and provide protection for the entire electrical system.

TVSS work by detecting electrical surges and diverting them away from the electrical system. When an electrical surge is detected, the TVSS activates and redirects the electrical surge to the ground, preventing it from damaging electrical systems and equipment.

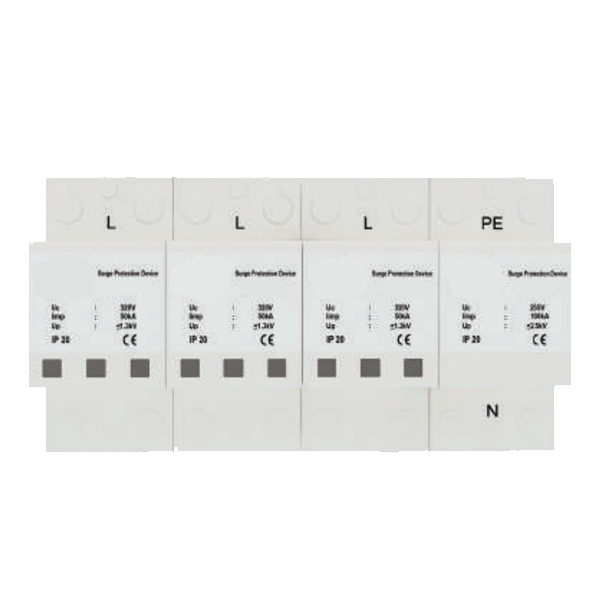

Surge Protective Devices (SPD)

SPD are a type of surge protection device that is designed to protect individual electrical panels and equipment from power surges. SPD are installed at the point where electrical power enters the electrical panel or equipment and provide protection for that specific panel or equipment.

SPD work by detecting electrical surges and diverting them away from the electrical panel or equipment. When an electrical surge is detected, the SPD activates and redirects the electrical surge to the ground, preventing it from damaging the electrical panel or equipment.

Power Conditioners

Power conditioners are a type of surge protection device that is designed to protect electrical equipment from power quality issues, such as voltage sags, voltage spikes, and electrical noise. Power conditioners work by filtering out electrical noise and smoothing out voltage spikes and sags, ensuring that electrical equipment receives clean and stable power.

Power conditioners are typically used in conjunction with TVSS and SPD to provide comprehensive protection against power surges and power quality issues.

Lightning protection systems are essential for buildings to minimize the risk of damage and ensure the safety of building occupants. Lightning arresters, such as the Franklin rod air terminal and the ESE lightning arrester, are critical components of a lightning protection system. Surge protection systems, such as TVSS, SPD, and power conditioners, are also important components of a comprehensive lightning protection system.

When choosing a lightning arrester and surge protection system for your building, it is important to consider the type of building, the height of the building, and the local weather patterns. It is also important to ensure that the lightning protection system is installed correctly and complies with national and international standards for lightning protection.

By implementing a comprehensive lightning protection system, building owners and occupants can rest assured that their building and electrical systems are protected from the potentially devastating effects of lightning strikes and electrical surges.