Lightning strikes can cause significant damage to buildings and structures, resulting in costly repairs and downtime. The installation of a lightning protection system is critical to protect against the unpredictable and potentially dangerous effects of lightning strikes. One type of lightning protection system is the Early Streamer Emission (ESE) lightning protection system. In this article, we will discuss the installation process of the ESE lightning protection system and the advantages it offers over other types of systems. We will also explore the benefits of using maintenance-free chemical earthing instead of traditional earthing methods.

What is an ESE Lightning Protection System?

An ESE lightning protection system is designed to protect buildings and structures from direct and indirect lightning strikes. It works by emitting a streamer, which is an ionized channel that is capable of attracting lightning strikes. The ESE lightning protection system has a unique design that enables it to emit the streamer earlier than other types of systems, giving it an advantage in attracting lightning strikes.

Installation Process of ESE Lightning Protection System

The installation process of an ESE lightning protection system is similar to that of a conventional system. However, there are some differences due to the unique design of the ESE system. The installation process typically involves the following steps:

Step 1: Site Assessment

The first step in the installation process is a site assessment. This involves assessing the building or structure to determine the level of protection required. The assessment takes into account the size and shape of the building, the location, and the surrounding environment. The assessment is critical to ensuring that the ESE lightning protection system is designed to provide the necessary level of protection.

Step 2: Design

Once the site assessment is complete, the design of the ESE lightning protection system can begin. The design takes into account the results of the site assessment and is tailored to the specific needs of the building or structure. The design includes the placement of air terminals, conductors, and grounding system.

Step 3: Installation of Air Terminals

The air terminals are the most visible part of the lightning protection system. They are installed on the roof of the building or structure and are designed to attract lightning strikes. The air terminals are typically made of SS Metal.

Step 4: Installation of Conductors

The conductors are the cables that connect the air terminals to the grounding system. They are designed to conduct the electrical charge from a lightning strike safely into the ground. The conductors are typically made of copper or aluminum and are installed along the roof and down the sides of the building.

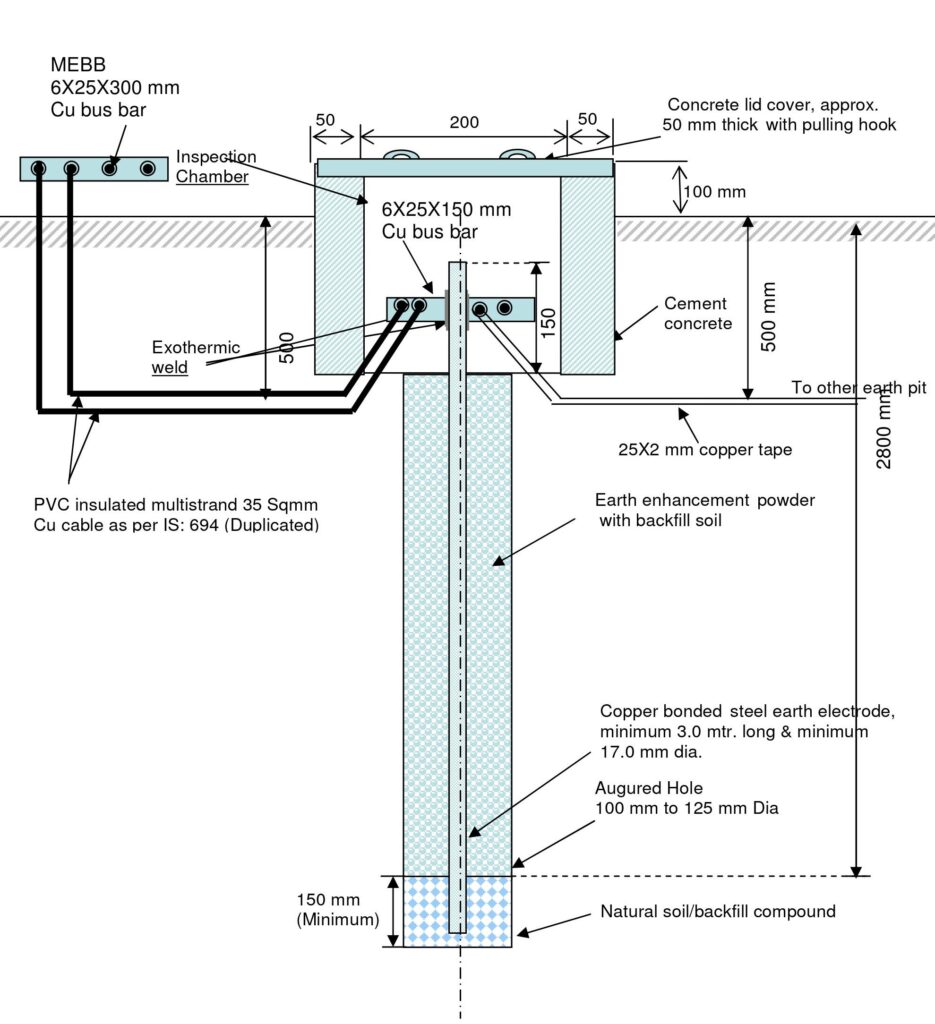

Step 5: Installation of Grounding System

The grounding system is designed to provide a path for the electrical charge from a lightning strike to safely dissipate into the ground. The grounding system typically consists of grounding rods and conductors that are buried in the ground. The grounding rods are installed at a sufficient depth to ensure a good connection with the soil.

Advantages of ESE Lightning Protection System

There are several advantages to using an ESE lightning protection system over other types of systems. These include:

Early Streamer Emission

The unique design of the ESE system enables it to emit a streamer earlier than other types of systems. This gives it an advantage in attracting lightning strikes, providing an extra layer of protection.

High Level of Protection

The ESE lightning protection system is designed to provide a high level of protection to buildings and structures. It is capable of protecting against direct and indirect lightning strikes, reducing the risk of damage and downtime.

Low Maintenance

The ESE lightning protection system requires little maintenance once it is installed. The air terminals and conductors are designed to withstand the elements and do not require regular maintenance.

Cost-effective

The ESE lightning protection system is a Cost-effective Lightning Protection Solution with Maintenance-Free Chemical Earthing.

In addition to the advantages of the ESE lightning protection system, there is another important aspect of lightning protection that should be considered: earthing. Earthing is the process of providing a path for the electrical charge from a lightning strike to safely dissipate into the ground. The traditional method of earthing involves using a grounding rod or plate that is buried in the ground. However, this method can be unreliable and requires regular maintenance to ensure a good connection with the soil.

A more modern and effective approach to earthing is the use of maintenance-free chemical earthing. This involves using a conductive compound that is mixed with the soil to create a low-resistance earth pit. The compound is designed to provide a permanent and reliable connection between the grounding system and the soil, reducing the need for regular maintenance.

Benefits of Maintenance-Free Chemical Earthing

There are several benefits to using maintenance-free chemical earthing over traditional earthing methods:

Reliable Connection

Maintenance-free chemical earthing provides a reliable connection between the grounding system and the soil. This ensures that the electrical charge from a lightning strike is safely dissipated into the ground, reducing the risk of damage and downtime.

Low Maintenance

Maintenance-free chemical earthing requires little to no maintenance once it is installed. This reduces the need for regular inspections and ensures that the grounding system is always functioning properly.

Longevity

Maintenance-free chemical earthing has a long lifespan, typically lasting for more than 20 years. This means that it is a cost-effective solution that requires minimal maintenance over its lifespan.

Cost-effective

Maintenance-free chemical earthing is a cost-effective solution that can save money in the long run. It requires minimal maintenance and has a long lifespan, reducing the need for expensive repairs and replacements.

In conclusion, the installation process of an ESE lightning protection system involves several steps, including site assessment, design, installation of air terminals, conductors, and grounding system. The ESE lightning protection system offers several advantages, including early streamer emission, high level of protection, low maintenance, and cost-effectiveness.

In addition to the ESE lightning protection system, the use of maintenance-free chemical earthing can provide a reliable and cost-effective solution for earthing. Maintenance-free chemical earthing offers several benefits over traditional earthing methods, including reliability, low maintenance, longevity, and cost-effectiveness.

By combining the installation of an ESE lightning protection system with maintenance-free chemical earthing, building owners and operators can ensure that their structures are protected against lightning strikes while minimizing the need for regular maintenance and expensive repairs.