The installation of a lightning protection system is a critical process that requires careful planning and adherence to safety standards. IEC 62561 is a standard that specifies the requirements for lightning protection system components, including their installation process. In this article, we will discuss the installation process as per IEC 62561 and the various steps involved in it.

Step 1: Risk Assessment

The first step in the installation process of a lightning protection system is to conduct a risk assessment. This assessment will determine the level of protection required for the structure and its contents. It will also identify potential hazards and the probability of a lightning strike.

The risk assessment should take into account the following factors:

- The height and shape of the structure

- The materials used in the construction of the structure

- The location and function of the structure

- The type and value of the contents of the structure

- The surrounding environment, including trees, power lines, and other structures

- The local lightning frequency and intensity

Once the risk assessment has been completed, the level of protection required for the structure can be determined. This will inform the design of the lightning protection system and the selection of appropriate components.

Step 2: Design of the Lightning Protection System

The next step in the installation process is the design of the lightning protection system. This involves selecting appropriate components and determining their placement on the structure.

The lightning protection system consists of the following components:

- Air termination system

- Down conductor system

- Earth termination system

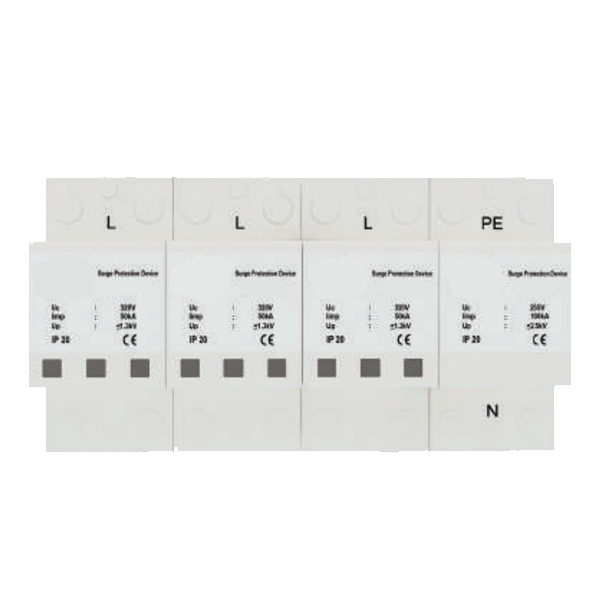

- Surge protection devices

The air termination system consists of lightning rods or air terminals that are installed at the highest point of the structure. The air terminals are designed to intercept the lightning strike and conduct it to the down conductor system.

The down conductor system consists of conductors that run from the air termination system to the earth termination system. The down conductors are designed to conduct the lightning strike safely to the earth.

The earth termination system consists of earth electrodes that are installed in the ground. The earth electrodes are designed to dissipate the lightning strike safely into the ground.

Surge protection devices are installed at the point of entry of electrical and electronic equipment into the structure. These devices protect the equipment from voltage surges that can be caused by lightning strikes.

The design of the lightning protection system must comply with the requirements of IEC 62561. The components must be selected based on their performance and safety requirements, and their placement must be determined based on the risk assessment.

Step 3: Installation of the Lightning Protection System

The installation of the lightning protection system must be carried out by qualified personnel who are familiar with the requirements of IEC 62561. The installation must comply with the relevant building codes and regulations.

The installation process can be broken down into the following steps:

- Installation of the air termination system

- Installation of the down conductor system

- Installation of the earth termination system

- Installation of the surge protection devices

Installation of the air termination system

The air termination system is installed at the highest point of the structure. The air terminals must be installed in a manner that allows for the interception of the lightning strike. They must be spaced appropriately to ensure that the entire structure is covered.

The air terminals must be securely fixed to the structure using appropriate fixings. They must be made of materials that are resistant to corrosion and mechanical damage. The air terminals must also be bonded to the down conductor system.

Installation of the Down Conductor System

The down conductor system is installed in a straight line from the air termination system to the earth termination system. The down conductors must be installed using appropriate fixings and must be secured to the structure at regular intervals.

The down conductors must be made of materials that are resistant to corrosion and mechanical damage. They must also be bonded to the earth termination system and the surge protection devices. The down conductor system must also be installed in a manner that prevents water ingress and damage to the structure.

Installation of the Earth Termination System

The earth termination system is installed in the ground. The earth electrodes must be installed in a manner that ensures good electrical contact with the surrounding soil. The earth electrodes must be spaced appropriately to ensure that the entire lightning protection system is properly earthed.

The earth electrodes must be made of materials that are resistant to corrosion and mechanical damage. They must also be bonded to the down conductor system and the surge protection devices.

Installation of the Surge Protection Devices

The surge protection devices are installed at the point of entry of electrical and electronic equipment into the structure. The devices must be installed in a manner that ensures good electrical contact and proper bonding to the down conductor system and earth termination system.

The surge protection devices must be selected based on their performance and safety requirements. They must be installed in accordance with the manufacturer’s instructions and the requirements of IEC 62561.

Step 4: Testing and Inspection

Once the lightning protection system has been installed, it must be tested and inspected to ensure that it is functioning properly. The testing and inspection process should be carried out by qualified personnel who are familiar with the requirements of IEC 62561.

The testing and inspection process should include the following:

- Verification of the components and their installation

- Measurement of the earth resistance of the earth termination system

- Measurement of the continuity of the down conductor system

- Verification of the bonding between components

- Verification of the surge protection devices

Any deficiencies or faults in the lightning protection system must be identified and rectified before the system is put into service.

Step 5: Maintenance

The lightning protection system must be regularly maintained to ensure that it continues to function properly. The maintenance should be carried out by qualified personnel who are familiar with the requirements of IEC 62561.

The maintenance should include the following:

- Inspection of the components for signs of damage or corrosion

- Inspection of the fixings and connections for tightness and security

- Measurement of the earth resistance of the earth termination system

- Measurement of the continuity of the down conductor system

- Verification of the bonding between components

- Verification of the surge protection devices

Any deficiencies or faults in the lightning protection system must be identified and rectified promptly to ensure that the system continues to provide adequate protection.

The installation process of a lightning protection system must be carried out carefully and in accordance with the requirements of IEC 62561. The process involves a risk assessment, design of the lightning protection system, installation of the components, testing and inspection, and maintenance.

The lightning protection system must be installed by qualified personnel who are familiar with the requirements of IEC 62561. The components must be selected based on their performance and safety requirements, and their placement must be determined based on the risk assessment.

Regular maintenance of the lightning protection system is critical to ensure that it continues to function properly. The maintenance should be carried out by qualified personnel and should include inspection of the components, measurement of the earth resistance and continuity of the down conductor system, and verification of the surge protection devices.

Adherence to the requirements of IEC 62561 is critical to ensure that the lightning protection system provides adequate protection to the structure and its contents. By following the installation process as per IEC 62561, the risk of damage or injury due to lightning strikes can be greatly reduced.