Lightning strikes are a common and often unpredictable natural phenomenon that can cause significant damage to buildings, equipment, and infrastructure. To mitigate the risk of lightning damage, lightning protection systems and lightning arresters are often used. While both of these systems are designed to protect against lightning strikes, there are important differences between them. In this article, we will explore the difference between lightning arresters and LPS (lightning protection systems), how they work, and when to use each one.

What is a Lightning Protection System?

A lightning protection system is a comprehensive set of measures designed to protect a structure or building from the effects of lightning strikes. It includes several components, including lightning rods, conductors, and grounding systems. A lightning rod, also known as an air terminal, is a metal rod or tube that is mounted on the roof of a building. It is designed to attract the lightning strike and conduct the current through a conductor to the grounding system. The conductor is a metal wire or cable that is attached to the lightning rod and extends down to the grounding system. The grounding system is a network of metal rods or plates that are buried in the ground, designed to dissipate the electrical charge into the earth.

The primary function of a lightning protection system is to provide a path of least resistance for the lightning strike, directing the electrical charge away from the structure and into the ground. The system does not prevent the lightning strike from occurring, but it does provide a safe path for the electrical charge to dissipate.

What is a Lightning Arrester?

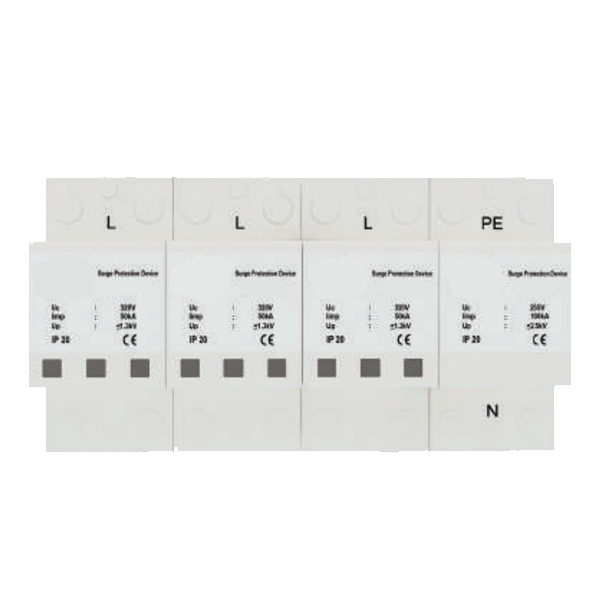

A lightning arrester, also known as a surge arrester or surge suppressor, is a device that is installed to protect electrical equipment from the damaging effects of electrical surges caused by lightning strikes. When lightning strikes an electrical system, it can cause a surge of electricity that can damage or destroy the equipment. A lightning arrester is designed to divert the surge of electricity away from the equipment and safely to ground, protecting the equipment from damage.

There are two types of lightning arresters: gap-type and valve-type. Gap-type arresters work by ionizing the air in the gap between two electrodes, which creates a low-impedance path for the lightning surge to travel to ground. Valve-type arresters use metal oxide varistors (MOVs) to absorb the energy of the surge and prevent it from damaging the equipment.

The primary function of a lightning arrester is to protect electrical equipment from the damaging effects of electrical surges caused by lightning strikes.

Differences between Lightning Protection Systems and Lightning Arresters:

While both lightning protection systems and lightning arresters are designed to protect against lightning strikes, there are several key differences between them.

Function: The primary function of a lightning protection system is to provide a path of least resistance for the lightning strike, directing the electrical charge away from the structure and into the ground. The primary function of a lightning arrester is to protect electrical equipment from the damaging effects of electrical surges caused by lightning strikes.

Components: A lightning protection system includes several components, including lightning rods, conductors, and grounding systems. A lightning arrester is a standalone device that is installed to protect electrical equipment from electrical surges.

Installation: A lightning protection system is installed on a building or structure, typically on the roof. A lightning arrester is installed near the equipment that it is designed to protect.

Maintenance: A lightning protection system requires regular maintenance and inspection to ensure that it is functioning properly. A lightning arrester also requires maintenance and inspection, but it is typically less complex than a lightning protection system.

When to use a Lightning Protection System:

A lightning protection system is typically used to protect buildings or structures from lightning strikes. They are commonly used on tall buildings, bridges, and other structures that are likely to attract lightning strikes. A lightning protection system is particularly important for buildings that contain sensitive equipment or materials that could be damaged by a lightning strike, such as hospitals, data centers, and chemical plants.

A lightning protection system is also recommended for buildings that are located in areas with a high frequency of lightning strikes or that are particularly vulnerable to lightning strikes due to their location or design.

When to use a Lightning Arrester:

A lightning arrester is typically used to protect electrical equipment from the damaging effects of electrical surges caused by lightning strikes. They are commonly used in power distribution systems, telecommunications systems, and industrial facilities that rely on sensitive electronic equipment.

A lightning arrester is particularly important for equipment that is located in areas with a high frequency of lightning strikes or that is particularly vulnerable to lightning strikes due to its location or design. For example, a telecommunications tower located in an area with a high frequency of lightning strikes would benefit from the installation of a lightning arrester to protect the sensitive electronic equipment.

Benefits of Lightning Protection Systems and Lightning Arresters:

Both lightning protection systems and lightning arresters offer important benefits for buildings, structures, and electrical equipment.

Benefits of Lightning Protection Systems:

Protection against lightning strikes: A lightning protection system provides a path of least resistance for the lightning strike, directing the electrical charge away from the structure and into the ground.

Protection for sensitive equipment: A lightning protection system can protect sensitive equipment from the damaging effects of a lightning strike.

Improved safety: A lightning protection system can help to reduce the risk of fire or other damage caused by a lightning strike.

Benefits of Lightning Arresters:

Protection for electrical equipment: A lightning arrester can protect electrical equipment from the damaging effects of electrical surges caused by lightning strikes.

Reduced downtime: By protecting electrical equipment from damage caused by lightning strikes, a lightning arrester can help to reduce downtime and improve productivity.

Cost-effective: Installing a lightning arrester is a cost-effective way to protect electrical equipment from damage caused by lightning strikes.

In conclusion, both lightning protection systems and lightning arresters play an important role in protecting buildings, structures, and electrical equipment from the damaging effects of lightning strikes. While both systems serve a similar purpose, there are important differences between them, including their function, components, installation, and maintenance requirements.

A lightning protection system is typically used to protect buildings or structures from lightning strikes, while a lightning arrester is typically used to protect electrical equipment from the damaging effects of electrical surges caused by lightning strikes. Understanding the differences between these systems and their respective benefits can help building owners and facility managers make informed decisions about which system to use to protect their property and equipment from lightning strikes.