Lightning is a powerful and potentially dangerous natural phenomenon that can strike without warning. It can cause significant damage to buildings, electrical systems, and people. To protect against lightning strikes, lightning protection systems (LPS) are installed in buildings and other structures. There are different types of lightning protection systems available, including direct and indirect lightning protection systems. In this article, we will discuss the different types of lightning protection systems in detail.

Direct Lightning Protection Systems

Direct lightning protection systems are designed to intercept and conduct lightning strikes to the ground, preventing damage to the structure and its occupants. These systems include lightning rods and early streamer emission (ESE) systems.

Franklin Rod LPS

The Franklin rod LPS, also known as a lightning rod or air terminal, is the oldest and most common type of lightning protection system. It consists of a metal rod or a conductor installed at the highest point of a structure, typically on the roof. The rod or conductor is connected to a grounding system that provides a low-resistance path for the lightning to travel to the ground.

When lightning strikes the structure, the Franklin rod LPS intercepts the strike and conducts it to the ground, dissipating the electrical energy harmlessly. The Franklin rod LPS works by creating a path of least resistance for the lightning to follow, reducing the risk of damage to the structure and its occupants.

Franklin rod LPS is suitable for most buildings and structures, including residential and commercial buildings, factories, and high-rise buildings. They are relatively inexpensive and straightforward to install.

ESE LPS

Early Streamer Emission (ESE) LPS is a newer type of lightning protection system that is designed to attract and capture lightning strikes before they can damage a structure. ESE LPS use a special ionization system that emits a streamer of ions into the air before a lightning strike occurs. This ionization system creates an upward streamer, which can attract the lightning strike towards the system.

ESE LPS is installed on the roof of the building and connected to the grounding system. They have a larger coverage area than Franklin rod LPS and are more sensitive to incoming lightning strikes. This makes them more effective at protecting large structures such as airports, wind turbines, and communication towers.

ESE LPS is more expensive than Franklin rod LPS, but they are more effective and provide a higher level of protection. They are also easier to install and require less maintenance.

Indirect Lightning Protection Systems

Indirect lightning protection systems are designed to protect electrical systems and equipment from the effects of lightning strikes, such as power surges and voltage spikes. These systems include surge protection devices and grounding systems.

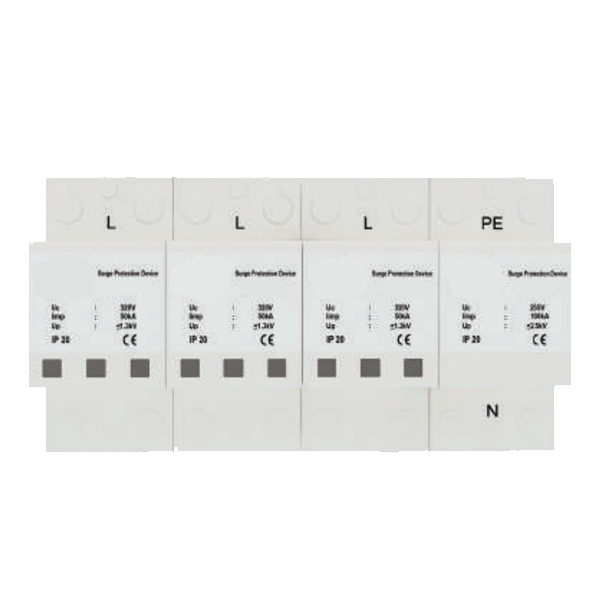

Surge Protection Devices

Surge protection devices (SPD) are electronic devices designed to protect electrical systems and equipment from power surges and voltage spikes caused by lightning strikes. They work by limiting the amount of electrical energy that can flow through the system, preventing damage to the equipment.

SPDs are installed in the electrical system, typically at the point where the power enters the building. They are also installed on individual pieces of equipment to protect them from power surges. SPDs are available in different types, including plug-in, panel-mounted, and whole-house units.

SPDs are effective at protecting electrical systems and equipment from lightning strikes, but they do not protect the structure from the physical effects of lightning strikes. They are also limited in their ability to protect against direct lightning strikes.

Grounding Systems

Grounding systems are an essential component of any lightning protection system. They provide a low-resistance path for the lightning to travel to the ground, dissipating the electrical energy harmlessly. Grounding systems consist of a network of conductive materials, including wires, rods, and plates, installed in the ground around the structure.

Grounding systems work by creating a path of least resistance for the lightning to follow, reducing the risk of damage to the electrical system and equipment. They also provide a stable reference point for the electrical system, reducing the risk of electrical shocks and fires.

Grounding systems are required by electrical codes and regulations and must be installed by qualified professionals. They must also be inspected and maintained regularly to ensure they are working correctly.

Lightning is a powerful and potentially dangerous natural phenomenon that can cause significant damage to buildings, electrical systems, and people. To protect against lightning strikes, lightning protection systems (LPS) are installed in buildings and other structures.

There are different types of lightning protection systems available, including direct and indirect lightning protection systems. Direct lightning protection systems are designed to intercept and conduct lightning strikes to the ground, preventing damage to the structure and its occupants. These systems include lightning rods and early streamer emission (ESE) systems.

Indirect lightning protection systems are designed to protect electrical systems and equipment from the effects of lightning strikes, such as power surges and voltage spikes. These systems include surge protection devices and grounding systems.

When selecting a lightning protection system, it is essential to consider the type of structure, the type of electrical system, and the level of protection required. It is also essential to hire qualified professionals to install and maintain the system to ensure it is working correctly.

In conclusion, lightning protection systems are an essential component of any building or structure. By installing the right system, property owners can protect their investment and ensure the safety of their occupants.