Exothermic Welding System

Exothermic welding, also known as exothermic bonding or thermite welding, is a type of welding that uses a chemical reaction to produce heat and create a permanent, reliable connection between two metal parts. NRB Enterprise is a company that specializes in the supply of Copper Exothermic Welding systems, including graphite moulds, welding powder, mould handle clamps, starting powder, and other relevant accessories.

The process of exothermic welding involves a chemical reaction between metal oxide and aluminum powder. When the two materials are mixed and ignited, the resulting reaction produces a high temperature that melts the metal parts and fuses them together. The resulting bond is strong, permanent, and resistant to corrosion, making it ideal for a wide range of applications.

NRB Enterprise offers a complete Copper Exothermic Welding system that includes all the necessary components and accessories for successful exothermic welding. Let’s take a closer look at each of these components and their role in the welding process.

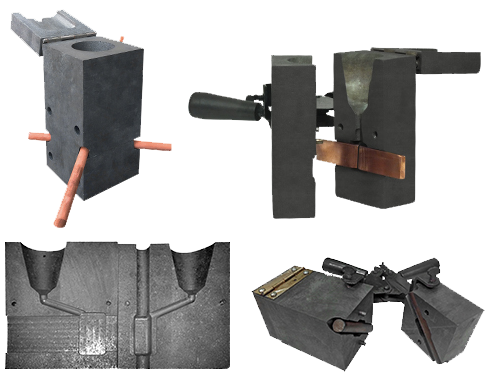

Graphite Mould

Graphite moulds are an essential component of the exothermic welding process. These moulds are used to hold the metal parts that need to be welded together and contain the welding powder during the welding process. Graphite is an ideal material for exothermic welding because it is an excellent conductor of heat, allowing for a more efficient and effective welding process.

NRB Enterprise offers a variety of graphite moulds in different sizes and shapes to accommodate a range of welding applications. These moulds are reusable, durable, and resistant to high temperatures, making them an economical choice for exothermic welding.

Welding Powder

Welding powder is a mixture of metal oxide and aluminum powder that is used to create the chemical reaction that generates the heat needed for exothermic welding. The exact composition of the welding powder depends on the type of metal being welded and the specific application.

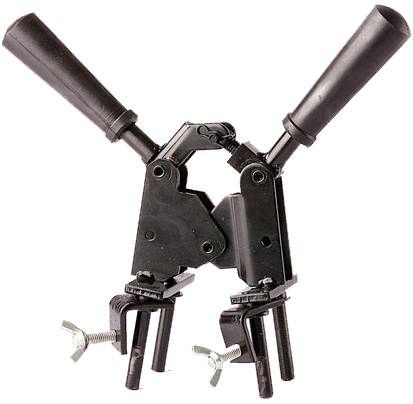

Mould Handle Clamp

Mould handle clamps are used to hold the graphite moulds in place during the welding process. These clamps are designed to be easy to use and provide a secure grip on the moulds, ensuring that they do not move or shift during the welding process. Mould handle clamps are an essential accessory for exothermic welding.

Starting Powder

Starting powder is a type of ignition powder that is used to initiate the chemical reaction between the metal oxide and aluminum powder in the welding powder. Starting powder is essential for ensuring that the welding process begins quickly and efficiently.

Other Relevant Accessories

NRB Enterprise also supplies a range of other relevant accessories for exothermic welding, including safety equipment, such as gloves and goggles, cleaning agents, and other tools and equipment necessary for a successful welding process. These accessories are designed to ensure that the welding process is safe, efficient, and reliable, and to provide customers with a comprehensive solution for their welding needs.

Benefits of Copper Exothermic Welding

There are several benefits of using Copper Exothermic Welding over other types of welding processes. One of the primary benefits is its ability to create a low-resistance connection. The high-temperature reaction creates a molecular bond between the copper parts, resulting in a strong, low-resistance connection. This makes it an ideal choice for electrical grounding, power transmission, and telecommunications applications.

Another benefit of Copper Exothermic Welding is its ability to create a strong and permanent connection that is resistant to corrosion and weathering. Unlike other types of welding processes, Copper Exothermic Welding does not rely on external materials such as flux, filler metal, or shielding gas. The resulting copper weld is strong and reliable, and it can withstand harsh environmental conditions.

Copper Exothermic Welding is also a safe and environmentally friendly option for welding. It produces minimal fumes and smoke, and the graphite mold can be reused multiple times, reducing waste. Additionally, Copper Exothermic Welding is a cost-effective solution for creating strong and permanent connections between copper parts. The initial cost of the equipment and materials is relatively low, and the resulting connections require little to no maintenance.

Overall, the Copper Exothermic Welding system offered by NRB Enterprise is an excellent choice for anyone looking for a reliable and efficient method for welding two metal parts together. Whether you’re working in construction, infrastructure, electrical, or other industries, NRB Enterprise’s Copper Exothermic Welding system is an investment that will pay off in the long run.